|

POLYETHYLENE PIPING SYSTEMS

|

|

| |

|

|

Kerotest Polyball 12 Inch Full Port |

|

|

Polyball Polyethylene 12" Full Port

|

- Features a 10.1" port opening.

- Gear box features a 6:1 ratio and is also sealed against outside contaminants making it virtually waterproof.

- Industry standard traceability code per ASTM F-2897.

- Available in SDRs from 9.0 to 21

- Produced in an ISO certified facility

|

|

Benefits & Features

The new Kerotest 12" POLYBALL® full port polyethylene ball valve delivers the highest flow of any 12" polyethylene ball valve made in America today. |

| |

|

|

Kerotest Polyball Natural Gas Valves |

|

|

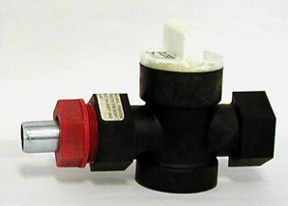

Polyball Polyethylene Valves for Natural Gas

|

- Full port and reduced port sizes from 1/2" to 12" IPS (20 to 315mm)

- Available with high head extensions in varying heights to meet specific installation requirements

- Temperature: From -20°F to 140°F (-29°C to 60°C)

- Pipe Connection: Butt fusion, mechanical fittings, electrofusion

- Stem Type: Standard or high head extended stem, length as required

- Kerotest Polyball polyethylene ball valves meet the requirements of ASME B16.40

- Manually operated thermoplastic gas shutoffs and valves in gas distribution systems

|

|

Benefits & Features

Custom, dedicated tooling and equipment have been developed for every valve size to achieve and maintain quality levels during production and minimize variation in all processes. All POLYBALL valves now feature the new industry standard tracking and traceability code per ASTM F2897 that allows instant access to individual valve specifications. With decoding software, simply scan the barcode to see the production date, size, material and valve type, lot code and more. |

| |

|

|

Kerotest Polyball Water Valves |

|

|

Polyball Water Valves

|

- Polyethylene valves for water and wastewater

- Full port or reduced port sizes

- Temperature: From 32°F to 140°F (0°C to 60°C)

- Pipe Connection: Butt fusion, electrofusion, or flanged end

- The Kerotest PolyballTM Water Valve meets or exceeds all industry standards

- All POLYBALLTM WATER valves are approved for use in potable water systems per NSF 61 requirements

|

|

Benefits & Features

The Polyball valve is Made-in-the-USA in Kerotest's state-of-the-art facility. Custom, dedicated tooling and equipment have been developed for every valve size to achieve and maintain quality levels during production and minimize variation in all processes. Valves are maintenance-free and corrosion-free, with drop-tight shutoff. Kerotest POLYBALLTM WATER Valves protect and preserve safe, healthy, leak-free drinking water distribution systems. |

| |

|

|

|

|

| |

|

|

Kerotest Strainer, Carbon Steel |

|

|

Kerotest Strainers |

- Up to 30% larger basket area.

- Interchangeable with valves - Standard ANSI B16.5 & 16.10 end to end dimensions.

- Elastomeric basket seal - eliminates potential leakage between basket and body.

- Reversible basket - for reverse flow applications.

|

|

Benefits & Features

Sizes 1" through 6" ANSI 150/300 lb. (Larger sizes available.) |

| |

|

|

Weld End Insulators |

|

|

Weld End Insulator |

- Exceeds strength of the pipe.

- No amperage leakage at 25,000 volts.

- Full 1" to 2" of insulation gap on the inside.

- Full 3" to 20" of insulation gap on the outside.

- No special weld precautions.

- No moving parts to fail and leak, zero environmental leakage.

- Economical - Beats the cost of an installed flange insulation joint.

|

|

Benefits & Features

Over 100,000 Kerotest weld end insulators in service. When stressed to fail these units remain electrically insulated. Tests show no current leakage with 10,000 volts of direct current. The seal is adiprene urethane under compression to assure zero leakage. |

| |

|

|

Zunt Monolithic Insulating Joint

|

|

|

Zunt Insulating Joints |

- Compact design. Low profile.

- Complete range of sizes and pressure classes.

- Each joint is internally lined with epoxy resin to effectively prevent bridging of the insulating gap.

- Eliminates electrical shorts and stops stray current in a pipeline system.

- Can be installed above or below ground.

- Long term electrical resistance does not depend on installer's assembly of an insulation kit.

|

|

Benefits & Features

The Kerotest Zunt insulating joints are manufactured to ISO 9001 standards. This solid weld design is more economical and comes in a broader range than any previous insulating joint from Kerotest, from 1/2" to 100", ANSI 150 to 2500. There is no assembly required and no maintenance. |

| |

|

|

|

|

| |

|

|

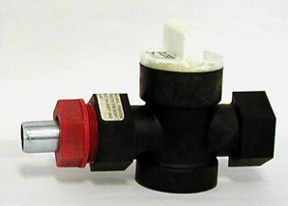

Kerotest Kerotite Curb Stop-Nylon Valves |

|

|

Kerotite Stop-Nylon Valves |

- Tested to ANSI B16.40

- Unobstructed circular opening

- Balanced plug design

- 12 degree shut off assurance

- 90 degree or 360 degree operation

- Rated for 100 PSI gas service

|

|

Benefits & Features

Can use curb or street key. Fits existing curb boxes. User friendly mechanical connections. |

| |

|

|

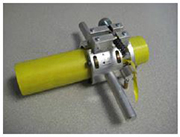

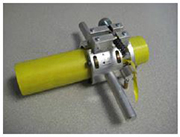

Quik-Cut Polyethylene Pipe Cutters |

|

|

Pipe Cutters

|

- No rough edges to cause leaking joints.

- Ideal for use by service crews and for field applications.

|

|

Benefits & Features

Now, a new easy simple way to cut plastic pipe. The Quik-Cut Polyethylene Pipe Cutter uses a ratchet drive principle for easy operation. Designed for long field service, its rugged construction guarantees a smooth square cut every time. |

| |

|

|

|

|

|

|

|

|

|

| Couplings |

Tapping Tees |

Fittings |

PE Pipe Split Peeler |

|