| *MAXIFLOW is a trademark of the General Electric Company or its affiliates. |

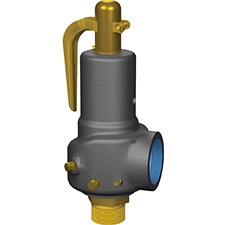

Type 1511 Steam Safety Valve |

|

|

|

CONSOLIDATED Brand Model 1511

- Cast iron safety valve for low pressure steam, steam heating boilers, and steam generators as well as air service applications.

- ASME Code Section I and VIII

- 1 1/2" through 6" Flanged or Threaded Design

- ANSI Class 250

- Orifice Sizes H-Q

- Temperature Range -20° F to 406° F

- Brass Trim is Standard with Stainless Optional

- Blowdown 4%

|

| |

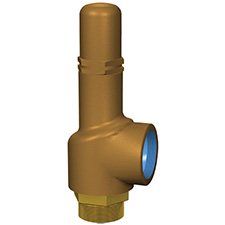

Type 1541/1543 Steam Safety Valve |

|

|

CONSOLIDATED Brand Model 1541/1543 Valves

- Designed for steam and other compressible fluids

- ASME Code Section I and VIII

- 3/4" through 2 1/2" Threaded Design

- Orifice Sizes D-J

- Pressure Range 5 to 350 PSI

- Temperature Range -20° F to 420° F

- Cast Iron Body with Brass Base and Trim. Bronze Bonnet is available and Stainless steel base and Disc are optional

- Blowdown 4%

|

| |

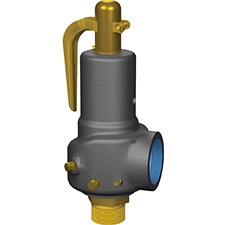

1700 MAXIFLOW* Brand Steam Safety Valve |

|

|

CONSOLIDATED Brand MAXIFLOW Brand 1700 Steam Safety Valve

- Premium high pressure Safety Valve

- ASME Code Section I and VIII

- Installed in a majority of Power Generating Stations world wide

- 1 1/2" to 6" Flanged or Weld Neck design

- ANSI Class 600 to 4500 PSI

- Temperature Range -20° F to 1120° F

- 3% Blowdown

- Alloy and Carbon Steel Body w/ Stainless Steel trim. Special alloys and trim are available

- GE proprietary THERMODISC brand seal provides superior repeatable seat tightness

|

| |

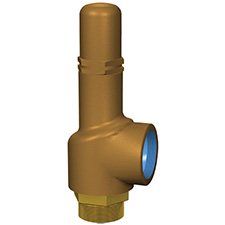

Type 1811 Steam Safety Valve |

|

|

CONSOLIDATED Brand Model 1811 Valve

- Cost effective high capacity flanged steel safety valve designed for steam service

- ASME Code Section I and VIII

- 1 1/4" through 6" Flanged Body

- ANSI Class 300 & 600

- Orifice Sizes F-Q

- Temperature Range -20° F to 1000° F

- Alloy and Carbon Steel Body w/ Stainless Steel trim

- 4% Blowdown

- GE proprietary THERMODISC brand seal provides superior repeatable seat tightness

|

| |

1900/P Process Safety Relief Valve |

|

|

CONSOLIDATED Brand Model 1900/P Valve

- Steam internal series valve designed for economizer and organic vapor service.

- Offers smooth performance with seat tightness even in difficult applications while providing low cost of valve ownership.

- 1" through 8" Inlet

- ANSI Class 150 through 2500

- Orifice Sizes D-T

- Temperature Range 90° F to 850° F

- Cast carbon steel body w/ Stainless Steel trim

- GE proprietary THERMODISC brand seal provides superior repeatable seat tightness

|

| |

Type 2478 Pressure Relief Valve |

|

|

CONSOLIDATED Brand Model 2478 Valve

- Designed as a totally enclosed thermal relief valve for non corrosive liquid service.

- Non-Coded

- 1/2" through 2-1/2" Threaded inlet

- Pressure Range 15 to 300 PSI

- Orifice Sizes D-H & J

- Temperature Range -325° F to 406° F

- Cast Bronze bonnet, brass base & trim and PTFE seats are standard.

- 7-15% Blowdown

|

| |

Type 2700 Steam Safety Valves |

|

|

CONSOLIDATED Brand Model 2700 Valve

- Designed to meet the fast growing co-generation and waste to energy markets

- ASME Code Section I and VIII

- 1 1/2" to 6" Flanged or Weld Neck design

- ANSI Class 600, 900 & 1500

- Temperature Range -20° F to 1050° F

- Orifice Sizes 1-Q

- Alloy and Carbon Steel Cast Body w/ Stainless Steel trim. Special alloys and trim are available

- 4% Blowdown

- GE proprietary THERMODISC brand seal provides superior repeatable seat tightness

|

| |

Type 3500 Electromatic Ball Valve |

|

|

CONSOLIDATED Brand Model 3500 Valve

- Designed to provide automatic or manual overpressure protection for steam boiler systems and can also be used in start-up and shutdown venting.

- Non Code

- ASME Code Section I

- 1 1/2", 2" & 2 1/2" either flanged or weld neck design.

- ANSI Class 1500 and 4500

- Temperature Range to 1150°

- Alloy Steel Body w/ Titanium alloy seat and ball

|

| |