|

|

|

| |

|

|

Model-1 Short Weld End Valve |

|

|

|

|

|

Kerotest Model-1 Short Weld End Valve

- 2 inch operation square malleable iron

- Buna "N", "O" rings, and "V" rings

- Brass packing actuator

- Steel packing gland cover

- Steel bonnet ASTM A-216 grade WCB

- Stainless steel stem

- Alloy steel cap screws --- ASTM A-574

- Soft iron bonnet gasket (Refinery gasket --- Fire proof)

- Steel body --- ASTM A-216 grade WCB

|

|

| Kerotest

Short Weld End Valve |

|

| |

Benefits & Features

Absolutely no maintenance. No gland tightening, no lubrication, no adjustment of any kind. Standard welding practices apply. Full opening with no significant pressure drop, lowest operating torque in the industry. Steel - Safety. Directional solidification weld ends meeting rigid code requirements. Seat test @ 110% of rated pressure, shell test @ 150% of rated pressure. Patented packing - no environmental leaking. Back seat - full containment of pressure below packing - no environmental leakage. Patented design. |

| |

|

|

Model-1 Long Weld End Valve |

|

|

|

|

|

Kerotest Model-1 Long Weld End Valve

- 2 inch operation square malleable iron

- Buna "N", "O" rings, and "V" rings

- Brass packing actuator

- Steel packing gland cover

- Steel bonnet ASTM A-216 grade WCB

- Stainless steel stem

- Alloy steel cap screws --- ASTM A-574

- Soft iron bonnet gasket (Refinery gasket --- Fire proof)

- Steel body --- ASTM A-216 grade WCB

|

|

| Kerotest

Long Weld End Valve |

|

|

Benefits & Features

Absolutely no maintenance. No gland tightening, no lubrication, no adjustment of any kind. Standard welding practices apply. Full opening - no significant pressure drop, lowest operating torque in the industry. Steel - Safety. Directional solidification weld ends meeting rigid code requirements. Seat test @ 110% of rated pressure, shell test @ 150% of rated pressure. Patented packing - no environmental leaking. Back seat - full containment of pressure below packing - no environmental leakage. Patented design. |

| |

|

|

Model-1 Screwed End Valve |

|

|

|

|

|

Kerotest Model-1 Screwed Weld End Valve

- 2 inch operation square malleable iron

- Buna "N", "O" rings, and "V" rings

- Brass packing actuator

- Steel packing gland cover

- Steel bonnet ASTM A-216 grade WCB

- Stainless steel stem

- Alloy steel cap screws --- ASTM A-574

- Soft iron bonnet gasket (Refinery gasket --- Fire proof)

- Threads - Female pipe threads per ANSI B21

- Steel body --- ASTM A-216 grade WCB

|

|

| Kerotest

Screwed End Valve |

|

| |

Benefits & Features

Absolutely no maintenance. No gland tightening, no lubrication, no adjustment of any kind. Full opening - no significant pressure drop, lowest operating torque in the industry. Steel - Safety. Seat test @ 110% of rated pressure, shell test @ 150% of rated pressure. Patented packing - no environmental leaking. Back seat - full containment of pressure below packing - no environmental leakage. Patented design. |

| |

|

|

Model-1 Weld by Flange 285 MOP;

Replaces Model 275 WOG |

|

|

|

|

|

Kerotest Model-1 Weld by Flange 285 MOP

- 2 inch operation square malleable iron

- Buna "N", "O" rings, and "V" rings

- Brass packing actuator

- Steel packing gland cover

- Steel bonnet ASTM A-216 grade WCB

- Stainless steel stem

- Alloy steel cap screws --- ASTM A-574

- Soft iron bonnet gasket (Refinery gasket --- Fire proof)

- Steel body --- ASTM A-216 grade WCB

|

|

| Kerotest

Weld by Flange 285 MOP |

|

|

Benefits & Features

Absolutely no maintenance. No gland tightening, no lubrication, no adjustment of any kind. Standard welding practices apply. Full opening - no significant pressure drop, lowest operating torque in the industry. Steel - Safety. Directional solidification weld ends meeting rigid code requirements. Seat test @ 110% of rated pressure, shell test @ 150% of rated pressure. Patented packing - no environmental leaking. Back seat - full containment of pressure below packing - no environmental leakage. Patented design. |

| |

|

|

Model 1 Weld by Flange 500 WOG/740 MOP;

Replaces M1 Weld by Flange 500/720 MOP |

|

|

|

|

|

Kerotest Model 1 Weld by Flange 500 WOG / 740 MOP

- 2 inch operation square malleable iron

- Buna "N", "O" rings, and "V" rings

- Brass packing actuator

- Steel packing gland cover

- Steel bonnet ASTM A-216 grade WCB

- Stainless steel stem

- Alloy steel cap screws --- ASTM A-574

- Soft iron bonnet gasket (Refinery gasket --- Fire proof)

- Steel body --- ASTM A-216 grade WCB

|

|

| Kerotest

Model 1 Weld by Flange 500/740 WOG |

|

| |

Benefits & Features

Absolutely no maintenance. No gland tightening, no lubrication, no adjustment of any kind. Standard welding practices apply. Full opening - no significant pressure drop, lowest operating torque in the industry. Steel - Safety. Directional solidification weld ends meeting rigid code requirements. Seat test @ 110% of rated pressure, shell test @ 150% of rated pressure. Patented packing - no environmental leaking. Back seat - full containment of pressure below packing - no environmental leakage. Patented design. |

| |

|

|

Model-1 Flanged End 285 MOP Valve

Replaces Model-1 Flanged End 275 MOP Valve |

|

|

|

|

|

Kerotest Model-1 Flanged End 285 WOG Natural Gas Valve

- 2 inch operation square malleable iron

- Buna "N", "O" rings, and "V" rings

- Brass packing actuator

- Steel packing gland cover

- Steel bonnet ASTM A-216 grade WCB

- Stainless steel stem

- Alloy steel cap screws --- ASTM A-574

- Soft iron bonnet gasket (Refinery gasket --- Fire proof)

- Steel body --- ASTM A-216 grade WCB

|

|

| Model 1 Flanged End |

|

| |

Benefits & Features

Absolutely no maintenance. No gland tightening, no lubrication, no adjustment of any kind. Standard welding practices apply. Full opening - no significant pressure drop, lowest operating torque in the industry. Steel - Safety. Seat test @ 110% of rated pressure, shell test @ 150% of rated pressure. Patented packing - no environmental leaking. Back seat - full containment of pressure below packing - no environmental leakage. Patented design. |

| |

|

|

Flanged End Valve 500 WOG/740 MOP

Replaces 500 WOG/720 MOP |

|

|

|

|

|

Kerotest Model-1 Flanged End 500 WOG / 740 MOP Natural Gas Valve

- 2 inch operation square malleable iron

- Buna "N", "O" rings, and "V" rings

- Brass packing actuator

- Steel packing gland cover

- Steel bonnet ASTM A-216 grade WCB

- Stainless steel stem

- Alloy steel cap screws --- ASTM A-574

- Soft iron bonnet gasket (Refinery gasket - fireproof)

- Steel body --- ASTM A-216 grade WCB

|

|

| Kerotest

Flanged End Valve |

|

|

Benefits & Features

Absolutely no maintenance. No gland tightening, no lubrication, no adjustment of any kind. Full opening - no significant pressure drop, lowest operating torque in the industry. Steel - Safety. Seat test @ 110% of rated pressure, shell test @ 150% of rated pressure. Patented packing - no environmental leaking. Back seat - full containment of pressure below packing - no environmental leakage. Patented design. |

| |

|

|

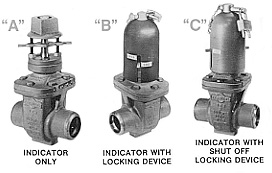

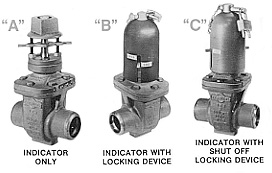

Model-1 Locking Devices |

|

|

|

Kerotest Model-1 Locking Device

- For use with the Kerotest natural gas valves which feature non-rising stems. EV-11 locking devices are also available.

- Easy to install

- Patented design

|

|

| Kerotest Locking Devices

|

|

| |

Benefits & Features

Absolutely no maintenance. No gland tightening, no lubrication, no adjustment of any kind. Standard welding practices apply. Full opening with no significant pressure drop, lowest operating torque in the industry. Steel - Safety. Directional solidification weld ends meeting rigid code requirements. Seat test @ 110% of rated pressure, shell test @ 150% of rated pressure. Patented packing - no environmental leaking. Back seat - full containment of pressure below packing - no environmental leakage. Patented design. |